- Home

- >

- News

- >

- Product News

- >

- S200G turbocharger core 1270-970-0216

S200G turbocharger core 1270-970-0216

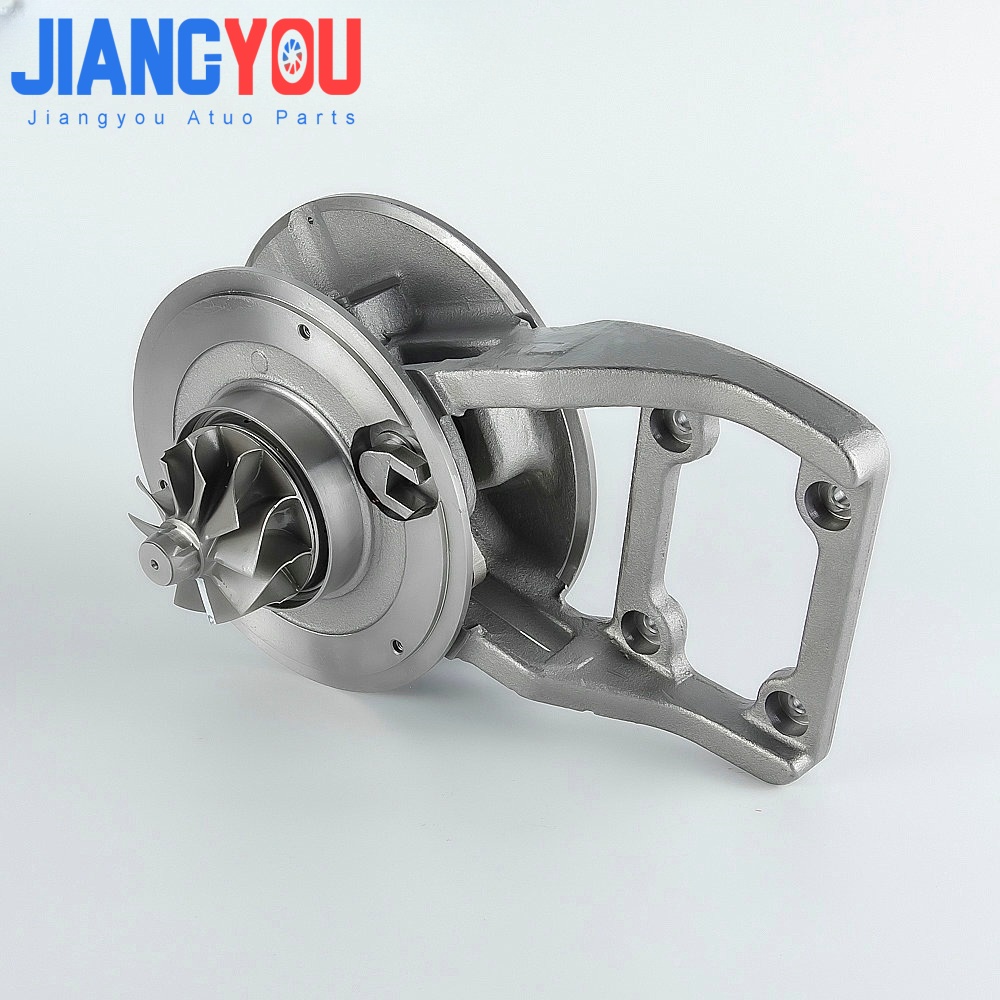

S200G turbocharger core 1270-970-0216 Turbo cartridge for DEUTZ Industrial TCD2013 Volvo L120E D7ELAE3

The S200G Turbocharger Core 1270-970-0216 Turbo Cartridge is a high-performance, durable replacement component

designed for use in industrial applications such as the DEUTZ TCD2013 and Volvo L120E D7ELAE3 engines.

As a critical part of the turbocharging system, the turbocharger core plays an essential role in optimizing engine power,

efficiency, and overall performance. In this in-depth review, we will explore the features, benefits, compatibility,

and maintenance considerations of the S200G turbocharger core, highlighting why it is an indispensable component for industrial machinery.

Introduction to the S200G Turbocharger Core

Turbochargers have become essential in modern internal combustion engines, particularly for heavy-duty and industrial machinery.

Their primary function is to compress the intake air entering the engine, increasing its density and, as a result, enhancing the engine's power output.

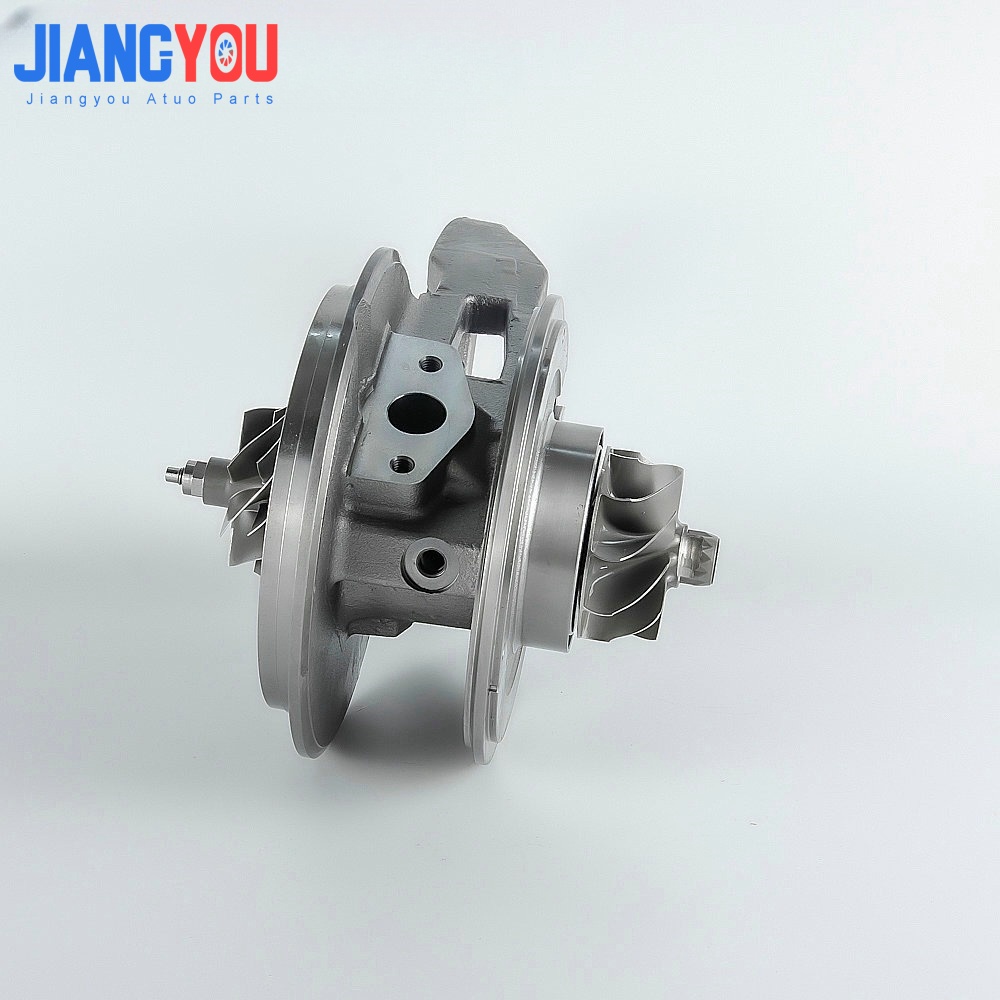

The S200G turbocharger core, also known as the turbo cartridge, is a key part of this process.

It houses critical components such as the turbine wheel, compressor wheel, shaft, and bearing system.

By upgrading or replacing a worn-out or damaged turbocharger core with the S200G unit,

operators can restore engine efficiency and prolong the service life of their equipment.

The S200G turbocharger core is specifically designed for use with DEUTZ Industrial TCD2013 engines and Volvo L120E D7ELAE3 engines.

These engines are widely used in applications such as construction, agriculture, and other heavy-duty industrial sectors.

The S200G turbocharger core ensures that these engines continue to perform at their best, delivering the power and reliability required for demanding tasks.

Key Features of the S200G Turbocharger Core

High-Performance Design

The S200G turbocharger core is engineered for maximum efficiency. It is designed to withstand the high pressures

and temperatures generated in industrial engine applications. The advanced design of the turbocharger includes precision-machined components,

such as a high-flow turbine and compressor wheels, which ensure excellent air compression and power delivery.

This results in increased engine power output, reduced fuel consumption, and lower emissions.

Durable Construction

Turbochargers in industrial machinery must operate in harsh conditions, including high heat and heavy load applications.

The S200G turbocharger core is constructed from high-quality materials, including corrosion-resistant alloys,

which ensure durability and extended service life. The core is built to handle the stresses of continuous operation

in demanding environments, making it a reliable choice for industrial engines.

Precision Engineering

The turbine and compressor wheels within the S200G core are precision-balanced to reduce vibration,

which can negatively impact engine performance and longevity. This balanced design improves the

efficiency of the turbocharger and ensures smooth operation under load. Additionally, the shaft and bearing

system are designed for minimal friction, which contributes to the core's overall reliability and performance.

Compatibility with DEUTZ and Volvo Engines

The S200G turbocharger core is specifically tailored for two popular industrial engine models: the DEUTZ TCD2013 and the Volvo L120E D7ELAE3.

These engines are commonly found in construction machinery, mining equipment, and agricultural vehicles.

The S200G core is designed to seamlessly integrate with these engine models, providing an easy and effective

replacement for damaged or worn-out turbochargers. Its compatibility ensures that operators can restore

engine performance without the need for extensive modifications.

Improved Fuel Efficiency

By optimizing the air intake and exhaust flow, the S200G turbocharger core improves combustion efficiency.

This translates into better fuel economy, which is especially important for operators seeking to reduce operational costs.

Lower fuel consumption also reduces the overall environmental impact, making the S200G core

an environmentally-friendly solution for heavy-duty machinery.

Enhanced Power Delivery and Acceleration

Turbocharging systems are essential for enhancing the power output and responsiveness of industrial engines.

The S200G turbocharger core helps engines such as the DEUTZ TCD2013 and Volvo L120E D7ELAE3 achieve smoother acceleration,

better torque, and more responsive power delivery. This is particularly valuable in applications such as construction equipment,

where quick acceleration and reliable power are essential for completing tasks efficiently.

Benefits of Using the S200G Turbocharger Core

Increased Engine Performance

The primary benefit of installing an S200G turbocharger core is the boost in engine performance.

Whether in a DEUTZ TCD2013 or Volvo L120E D7ELAE3 engine, the turbocharger core increases the intake air pressure,

enabling the engine to burn more fuel and produce more power.

This results in enhanced engine efficiency and better performance in demanding industrial applications.

Cost-Effective Solution

Replacing a worn-out turbocharger core with an S200G unit is a cost-effective solution for operators

looking to restore engine performance without the need for expensive, full turbocharger replacements.

The S200G core is designed for easy installation, making it a convenient and affordable

option for keeping equipment running smoothly.

Reduced Downtime

Because the S200G turbocharger core is engineered for reliability and ease of installation,

operators experience minimal downtime when replacing a damaged or worn turbocharger.

This is critical for industries where equipment downtime can result in significant financial losses.

The quick installation and long-lasting performance of the S200G core help keep operations running efficiently.

Lower Maintenance Costs

The durable construction and precision engineering of the S200G turbocharger core contribute to reduced maintenance costs over time.

The high-quality materials used in its manufacturing ensure

that the core can withstand the rigors of heavy-duty operations without requiring frequent repairs or replacements.

Maintenance and Care of the S200G Turbocharger Core

To maximize the lifespan and performance of the S200G turbocharger core, regular maintenance is essential.

Operators should ensure that the engine’s oil and filtration systems are clean and well-maintained,

as poor lubrication or contamination can cause damage to the turbocharger bearings.

Routine inspection of the turbocharger system for signs of wear or damage,

such as excessive shaft play or oil leaks, can help prevent costly repairs and downtime.

Conclusion

The S200G Turbocharger Core 1270-970-0216 Turbo Cartridge is an exceptional choice for operators seeking to optimize

the performance of their DEUTZ TCD2013 and Volvo L120E D7ELAE3 engines. Its durable construction, high-performance design,

and easy compatibility with industrial engines make it an invaluable component for maintaining the efficiency

and power of heavy-duty machinery. By investing in the S200G turbocharger core, operators can enjoy improved fuel economy,

increased engine power, reduced downtime, and cost-effective maintenance,

all while ensuring their equipment operates at peak performance.