- Home

- >

- News

- >

- Industry News

- >

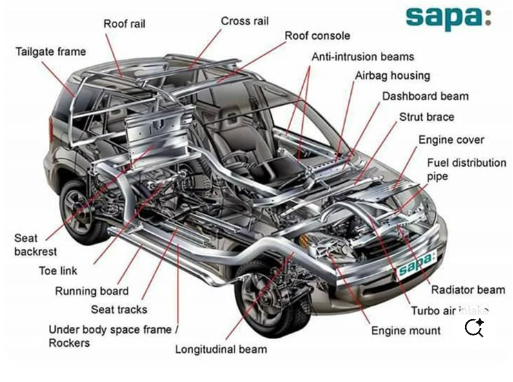

- The overall structure of a fuel vehicle

The overall structure of a fuel vehicle

Power system (engine system)

• Engine (internal combustion engine): core component, converting fuel chemical energy into mechanical energy.

◦ Crank-connecting rod mechanism: piston reciprocating motion → crankshaft rotational motion.

◦ Valve mechanism: control the opening and closing of intake/exhaust valves (camshaft, valves, etc.).

◦ Fuel supply system: fuel tank, fuel pump, fuel injector (mainly electronic fuel injection system), fuel filter.

◦ Ignition system (gasoline vehicle): spark plug, ignition coil (diesel vehicle is compression ignition).

◦ Cooling system: water pump, radiator (mainly water cooling) to prevent overheating.

◦ Lubrication system: oil pump, filter, reduce friction loss.

◦ Exhaust system: exhaust manifold, catalytic converter, muffler, handle exhaust gas and reduce noise.

2. Transmission system

• Clutch (manual gear): separate/engage the engine and transmission.

• Transmission: adjust torque and speed (manual/automatic/dual clutch/CVT).

• Drive shaft: transmits power to the differential in rear-wheel drive/four-wheel drive vehicles.

• Differential: distributes power and allows wheel speed difference (front-wheel drive vehicles are integrated into the transaxle).

3. Driving system

• Frame/chassis: load-bearing (sedan) or non-load-bearing (off-road vehicle, truck).

• Suspension system: shock absorbers, springs, control arms, divided into independent/non-independent suspension.

• Wheels and tires: wheel hubs, tires (tread, sidewalls, etc.), provide grip.

4. Steering system

• Mechanical steering: steering wheel, steering column, gear rack mechanism.

• Power steering: hydraulic power steering (HPS) or electric power steering (EPS).

5. Braking system

• Service brake: disc/drum brake, hydraulic drive (brake master cylinder, slave cylinder).

• Parking brake: mechanical handbrake or electronic handbrake.

• Electronic assistance: ABS anti-lock braking system, ESP body stability system.

6. Body and safety structure

• Body type: load-bearing (lightweight) or non-load-bearing (high rigidity).

• Covering parts: doors, hood, bumpers, etc.

• Safety design: anti-collision beams, airbags, body energy absorption area.

7. Electrical and electronic systems

• Power system: battery (starting power supply), generator (charging during operation).

• Starting system: starter, ignition switch.

• Lighting and signal: headlights, taillights, turn signals.

• Instruments and infotainment: instrument panel, central control screen, navigation.

• Air conditioning system: compressor, condenser, evaporator.

• Electronic control unit (ECU): engine control module (ECM), transmission control module, etc., integrated sensor network.

Additional explanation

• Emission control system: including EGR valve, catalytic converter, etc., to reduce pollutant emissions.

• Difference in drive form: front-wheel drive vehicles have no drive shaft, and power is transmitted through a variable speed drive axle; four-wheel drive vehicles add a transfer case.

• Modern electronics: rely heavily on ECU and CAN bus communication to achieve intelligent control.

Summary The structure of fuel vehicles is a high degree of integration of mechanics and electronics, and the various systems work together to ensure power, safety and comfort. With the development of technology, the degree of electronics is increasing, but the core mechanical principles remain unchanged. Although new energy vehicles have different structures (such as the three-electric system), the architecture of fuel vehicles is still the foundation of automotive engineering.